Product Description

Hager+ Elsasser – WATER MANAGEMENT

Competence and Experience

All Technologies

Irrespective of fuel and output of a power station, we develop a customized water engineering solution for your power station. All raw water sources are feasible: Whether surface, well or sea water, cooling tower discharge or sewage treatment plant effluent are used, our treatment concept always meet the highhest requirements.

Treatment of cooling tower make-up water is done using physical, chemical and/or membrane process, and condensate is treated by means of cartridge filters and/or ion exchangers. The deionisation plant for make-up water treatment is designed with ion exchangers, membrane processes or a combination of both. Our own processes are used for treatment of waste water from flue gas desulphurisation and wet ash removal and have proved to be successful in many plants.

All Field of Use

Among out long-time customers are renowned utility companies, municipal works, industrial power stasion operators and general contractors. The close collaboration with our customers and the successful implementation of numerous projects in all fields of water treatment form the basis of our success. Maximum effectiveness are importance objective for us.

Cooling Tower Make-up Water Treatment

The cooling water system of a power station mainly comprises the natural draught wet cooling tower, the primary cooling water system with make-up water addition, the secondary cooling water system, as well as the make-up cooling water system.

The expanded steam is condensed to water in the condenser. The heat of condensation released is discharged to the atmosphere via circulating primary cooling water in the cooling tower. A portion of the cooling water is blown down in order to guarantee the reuired cooling water quality. The evaporation and blow-down losses are made up by adding treated cooling tower make-up water.

Normally surface water is available as the raw water source. The main tasks of a cooling tower make-up water treatment plant are the reduction of general suspended matter and precipitated water hardness:

• Pressure filter (multimedia filter), or ultrafiltration as an alternative

• Open Filter: FILTRO.G system

• Flocculation/precipitation/sedimentation: FLOCOPAC® System with sludge treatment by means of a chamber filter press or belt-type filter press

• Biocide, sulfuric acid and hardness stabilizer dosing.

FLOCOPAC®-LC

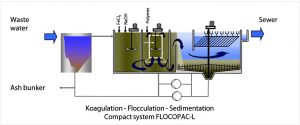

In order to obtain very low discharge values in a reliable and cos-effective way, we have been successfully using FLOCOPAC®.L or FLOCOPAC®.LC compact flocculator for treatment of the cooling tower make-up water for many years.

In addition to the flocculation reaction, optimized by sludge recycling, and the high sedimentation rate, the FLOCOPAC®.LC also offers the advantage of being insensitive to raw water quality variations. Furthermore, thanks to the compact design, up to 90% of the area can be saved compared to a conventional flocculation sedimentation and filtration plant.

Condensate Polisher

State-of-the-art power station boilers need feedwater with low salt and corrosion product content. Normally, a condensate polisher is installed to provide boiler feedwater of the required quality in the water-steam circuit of a power station.

The following equipment is used for this:

• Pressure filter (cartridge filter)

• Ion exchanger

• Adsorption (activated carbon) process

The circuitry, the necessary process stages and throughput are influenced by number of boundary conditions. These include, in particular:

• Use of the power station in the base-load range, or in the medium or peak load range

• Conditioning of the water-steam circuit (“alkaline” or “combined operation”)

• Use of the power station for power and/or heat generation or steam displacement

• Materials and fuel used

Two circuits for the condensate polisher in the water-steam circuit are shown below. These also result in the necessary boundary conditions for the plant concept.

The condensate polisher is either connected directly to the main condensate stream or as a bypass. In addition to the operational dependability, the economic aspects (capital and operating cost) are thoroughly assessed within the scope of the plant selection and planning. Especially in the selection and operation of ion exchangers, H+E can fall back on comprehensive experience and thus propose the optimum alternative from parallel flow/counterflow processes and internal or external regeneration.

Deionisation Plant

A further increase of the efficiency of power stations requires, among other things, higher steam pressure and temperature. Besides the appropriate materials for the turbine, ever higher requirements are palced on the steam purity and, thus, on the quality of the boiler feed water in the power station’s water-steam circuit. Very low residual conductivities and low silicic acid concentrations must be achived, in particular. The same also applies to organic substances.

Boiler feed water losses int the water-steam circuit are covered by a deionisation plant (boiler feed make-up water or deionised water). H+E provides concepts for optimsed solutions for your spesific requirements. These concepts are based on ion exchange, membrane, as well as physical degassing technologies and their combination. This allows deionised water of the appropriate quality to be provided even from difficult raw waters.

Ion exchange systems can be used in many ways for deionisation. The classical process stages, such as water softening by means of a strong-acid ion exchage resin in the sodium cycle, decarbonization by means of a weak-acid ion exchange resin, deionisation in combination with different resin types, as well as cascade degasifiers, membrane degasifiers or vacuum degasifiers have proven successful.

For treatment of salt-containing and organically loaded raw waters, the use of membrane technologies is the best solution, e.g. reverse osmosis combined with the mixed-bed ion exchangers.

ROCEDIS®

As a consequent further development of the membrane processes for deionisation, we have developed a modular and chemicals-free solution: ROCEDIS® – the peerfect combination of reverse osmosis, membrane degasification and electro-deionisation.

Waste Water Treatment from Flue Gas desulphurisation Plants

Flue gas desulphurisation (FGD) plants mainly operate on the wet absorption principle with calcium hydroxide or limestone suspension as the absorbent and re-usable gypsum as the end product. Waste water is produced during this process, the composition and volume of which are influenced by many factors.

FGD waste waters are oversaturated with gypsum, may have very high solid matter concentrations, frequently have a high chloride content and contains dissolved metals. In addition, these waste waters are highly abrasive, so that the selection of suitable treatment steps and appropriate materials is of great importance.

Our treatment concepts are tailored to your specific needs. Our references from numerous projects comprise the following treatment steps, depending on the task:

• Sulphite oxidation

• Removal of the gypsum oversaturation and sulphate precipitation in steps

• 2-stage flocculation/precipitation/sedimentation plant with neutralising precipitation of the metals and their conversion into poorly soluble hydroxides, or partly into basic carbonates, as well as organo-sulfide precipitation in the second stage

• Sludge thickening

• Sludge dewatering

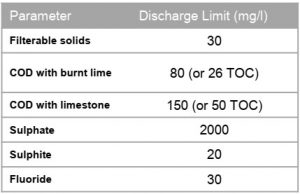

The treated waste water is discharged directly into the receiving water, the quality to be achived varying from country to country. FGD waste waters with higher ammonium concetrations may require secondary treatment. We have appropriate solutions for the required desorption of the ammonium with absorption system connected downstream.

Process Waste Water Treatment Plant

The ash deposited at the base of the boiler is collected in the wet ash removal system. This solids-containing waste water is uasually treated in a process waste water treatment plant. The water is first into preliminary clarifier, into which further solids-containing partial waste water streams are fed as required.

In most cases, a sedimentation plant with lamella separators is suited for treatment of this type of waste water. Here, our tried-and-tested FLOCOPAC®.L system is used.

Usually, a thickener is connected downstream of the sedimentation stage. In specific cases, further COD reduction may becme necessary in an additional stage.

Besides reliable compliance with discharge limit values, a high-effieciency design with optimised chemical demand and low space requirement is particularly relevant to ensure cost-effective plant operation.

The process waste waters from the wet ash removal plant are covered by Annex 31 Para. 2.4 of the Waste Water Ordinance.

“Effluent free” Water Concepts for Any Site

In arid zones, the raw water available for operation of the entire power station is frequently sea water, brackish water or biologically treated water from municipal sewage treatment plants because the fresh water resources are exclusively reserved fro drinking water production. By combining the optimum process chains, reliable treatment is possible in any case.

Due to the globally growing ecological awareness, the limit values for discharge of waste water into rivers are continually become more stringent. In some arid zones, no receiving water is available to receive the treated waste water. For such cases, we have developed and realized Zero Liquid Discharge concepts.

Zero Liquid Discharge

In 2006, a boiler feed water treatment plant for an 800 MW power station in Italy had to be constructed under such difficult conditions: Effluent from a sewage treatment plant was available as the raw water source; the waste waters produced in the station, such as filter rinsing water and boiler blow-down water, were also treated in order to obtain a Zero Liquid Discharge:

Pre-treatment

• Flocculator to reduce the filterable subtances and organic load

• Multimedia and ultrafiltration for further reduction of the organic fouling potential and chlorine dioxide dosing

Demineralization

• Activated carbon filtration, designed as a bio-filter, to reduced the COD and DOC value and to reduce the ammonium

• Permeate-staged reverse osmosis system for demineralization

• Working mixed-bed exchanger system for fine demineralization

Waste water treatment

• Concentrate reverse osmosis treatment for further concentration of the waste water produced

• Batch neutralization of waste waters upstream of the evaporator stage followed by a crystallization evaporator to produce a salt slurry that can be deposited on a landdfill

• Sludge treatment for thickening of the sludge produced in the flocculator

Dependable Service According to Your Needs

Professional customer service is essential in order to be able to operate process water plants in a trouble-free and cost effective manner for many years. Our service offerings range from the elimination of the faults up to complete management of your water treatment plants.

Our local service engineers, with their many years of experience with water treatment and process control, are your dependable partners and problem solvers for day-to-day plant operation.

H+E offers you practice-oriented services and wall-to-wall solutions. For temporary water supply at commissioning and during shutdowns, we plan your secure supply by means of mobile containers and plants.

• Available 24 hours a day and 365 days a year

• Individual contracts for extremely short standby on call

• Analysis service by our own laboratory

• Spare parts and operating supplies management by means of outline agreements

• Stocking of spare parts of local stocks to ensure short delivery times

• Service by local engineers, or plant management on site

• Online monitoring of water plants

Within the scope of audits, we assess all aspects of water treatment and use for the purposes of potential savings, and we evaluate the state of the plants and the process technology used.

We assume responsibility for continuous improvement, optimization and conservation of the value of your plants by means of sophisticated service concept under plant management models.

Reviews

There are no reviews yet.